It was the year 1980. Engineers at Audi's HQ cooked up an engineering marvel that was set to change the automotive world for good. It was the Monte Carlo rally stage and in just 10 mins, an Audi Quattro WRC race car overtook the mad machine, the Lancia Stratos, which started a minute before the German racer. The Audi Quattro took the world of rallying by a storm and won the championship back to back. It was an amazing marketing campaign to push the Quattro brand in the consumer market. Forty years in the future and Quattro is a household name now.

The Quattro, slingshot Audi to new heights in the world of motorsports, be it WRC, Trans-Am racing or be it the success of R-18 e-tron at the 24 hours of LeMans. The AWD technology, back in the 70s’ was showcased by Volkswagen’s offroader, the Iltis. The technology was then brought under Audi’s banner which then took a shape of the intelligent all-wheel-drive system we all know today. Over these 40 years, the system has been worked upon by some of the world’s best engineers and the initial system gave birth to numerous iterations of the Quattro we know and experience today.

How did the Audi Quattro system work in its initial years?

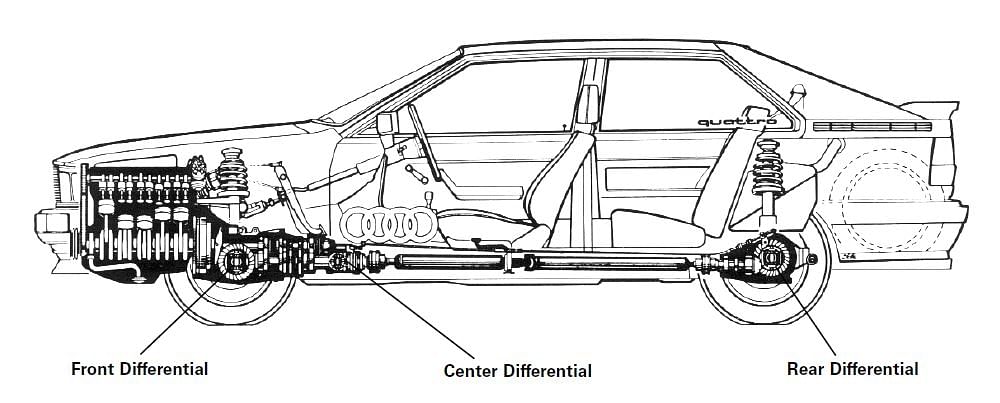

Initially, the Quattro system was purely mechanical and made use of three differentials which distributed power in a 50:50 ratio between the front and rear axles. The central differential had a locking mechanism which could be controlled by the driver using a vacuum-assisted switch. Switching the central diff would power both the axles equally thereby avoiding slip.

In normal conditions, the differentials remain open in order to let the wheels rotate independently. While taking a turn, the inside wheel takes the inner line and thus travels a shorter distance compared to the outer wheel which takes the outer and a wider line and thus travels a longer distance. This wheel speed difference is why we need differentials in the first place. When the differential is locked, the power is distributed evenly across the axles for better traction.

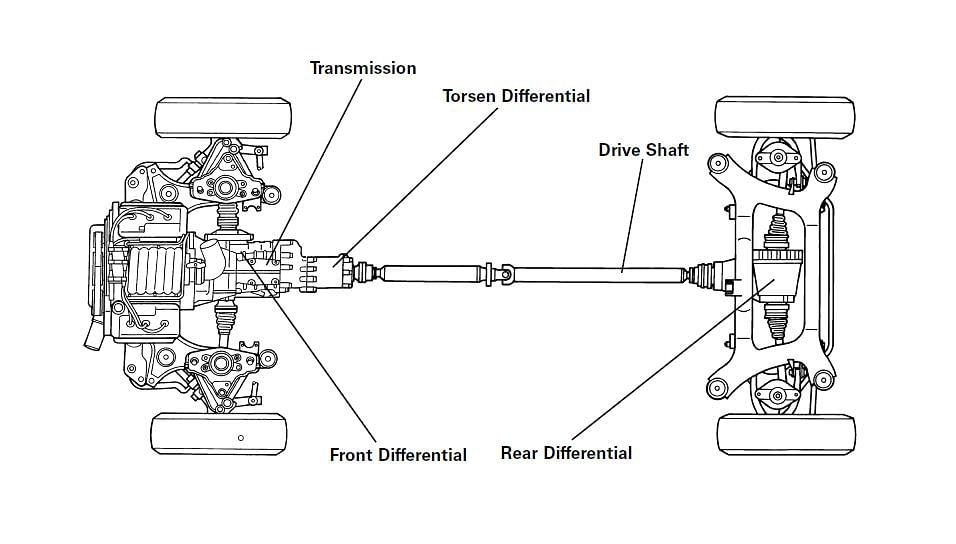

In the late 80s’, Audi engineers found a way to eliminate the use of engaging the differential manually. The mechanical center differential was replaced by a Torsen or torque-sensing differential. The Torsen differential is an ingenious piece of kit that houses a set of spur gears around a worm gear setup. As soon as a slip is detected, the planetary gear set up of both the axles lock as the worm gear can only shift power in one direction. This locks the differential indefinitely and instantly. To this day, Torsen differentials are being used heavily.

The new-age Audi Quattro AWD system and it's Working

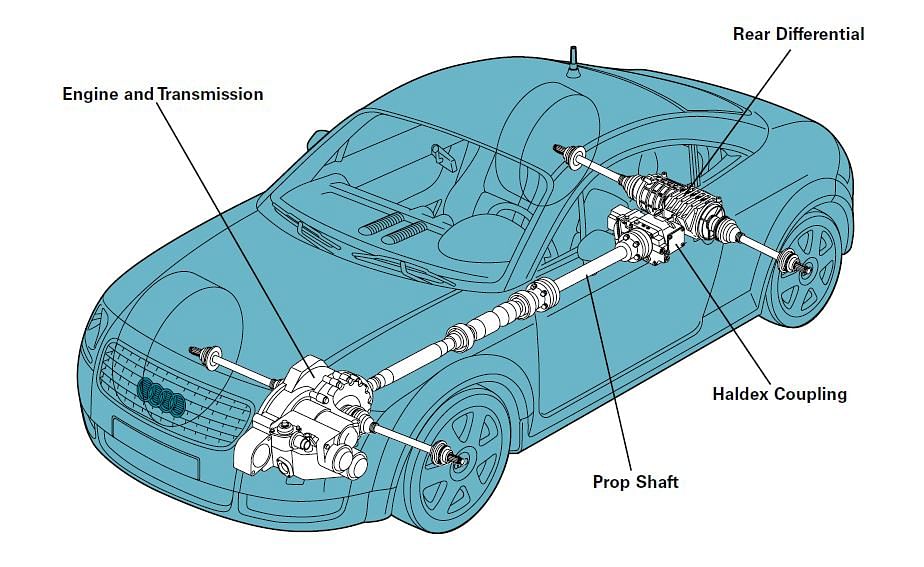

Automotive engineering has seen a ton of advancements over the years. The concept of sending power to the front wheels revolutionized the industry. Eliminating the need of feeding the power to the rear wheels freed up a chunk of room on the inside which made the design even more efficient. In the same footprint, engineers could carve out a roomier cabin with a cavernous boot at the back. Due to this, the front-wheel-drive configuration lost out on all-weather capability which was eventually taken care of by a Haldex designed AWD system.

To save on space, FWD cars usually have transversely mounted engines which made the traditional center differential placement next to impossible. In the FWD configuration, manufacturers use something called a transaxle which is basically an amalgamation of the gearbox and the differential in one coupling. The differential sits on the side of the gearbox sending power to the two front wheels via two shafts of staggered lengths.

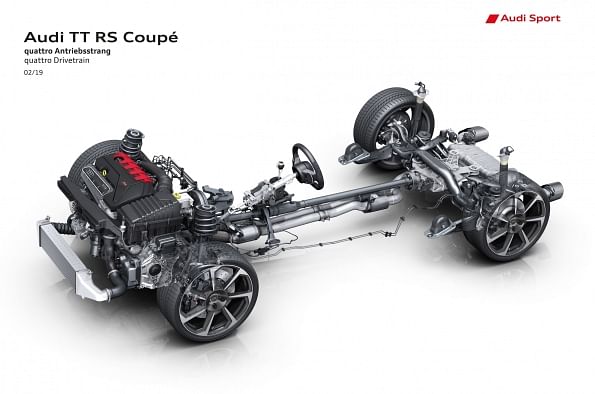

In a Haldex system, a prop shaft runs from the transaxle to the Haldex coupling placed in front of the rear axle. The Haldex differential then transfers the power to the back. When a slippery situation arises, a set of sensors senses the difference of speed between the input and the output shaft, thereby actuating the hydraulic assembly, which functions as a clutch, which joins the front and rear axles making all-wheel-drive possible.

This type of Quattro system can be found in the likes of the 2020 Audi TT, A3, S3, and RS3 and some SUVs like the Audi Q3 Quattro. New age cars use an array of sensors that gather slip from the tires, brakes, vehicle speed with respect to the engine RPM and throttle positioning. The shift from FWD to AWD is almost seamless. This system is much more fuel-efficient as the power won’t be transferred to the rear axle in normal driving conditions saving on frictional and drivetrain losses. It’s the best of both worlds.

Today’s Quattro. Different forms, similar functions.

Audi started with a fundamental concept of shifting the power to the wheels with the most amount of traction for optimum performance in hairy situations.

Today, Audi cars are equipped with five different kinds of Quattro AWD systems, all of which share their DNA with the OG Audi Quattro of the 80s’.

- Quattro AWD system for cars sharing the MLB platform and make use of the 8-speed conventional automatic like the 2020 Audi Q7 and the 2020 Audi Q8.

- Quattro AWD system for cars based on MLB Evo with a 7-speed dual-clutch gearbox like the 2020 Audi A4 Allroad.

- Quattro AWD for cars with transversely mounted engines built on the MQB platform like 2020 Audi TT, 2020 Audi A3, S3, and RS3 and some SUVs like the 2020 Audi Q3 Quattro.

- A sporty and rear-biased Quattro AWD system for the Audi R8.

- A new, state of the art Quattro AWD system for the E-Tron using one electric motor on each axle.

What about the power break-up?

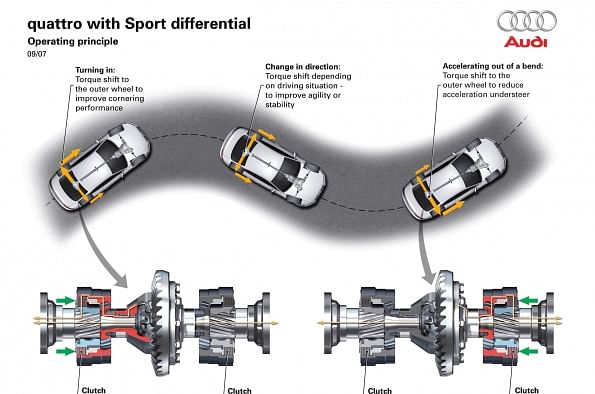

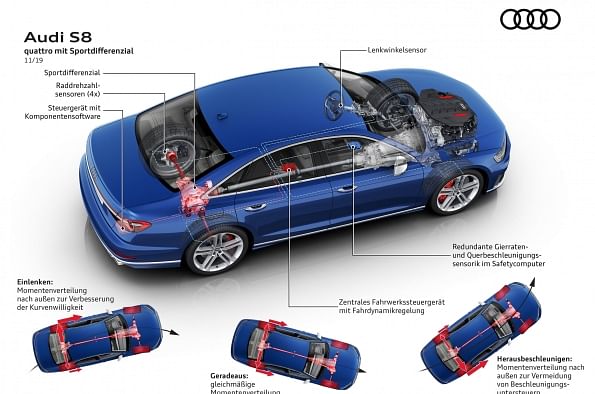

In ideal conditions, everyday Audi workhorses transfer 40% of the power to the front and 60% to the rear end. In sketchy conditions, the Quattro system can transfer up to 70% to the front and a heavy 85% at the back. Audi’s range of vehicles has grown over time and now has a totally separate sports division which rolls out Audi cars with S and RS badges. In cars like 2020 Audi S8 and 2020 Audi RS5, the Audi sport differential is housed which makes use of clever torque vectoring.

When cornering hard, the inside wheel loses the grip first as the weight transfer tips the car in the outward direction due to centrifugal force. The inside wheel rotation is controlled by applying brakes and depending on the situation, close to 100% power can be transferred to the outside wheel with the most amount of traction which helps in the rotation of the car around a corner. The car sticks to the ground like its superglued and can use all this traction to rocket out of the apex.

How does the Audi R8 V10’s Quattro System work?

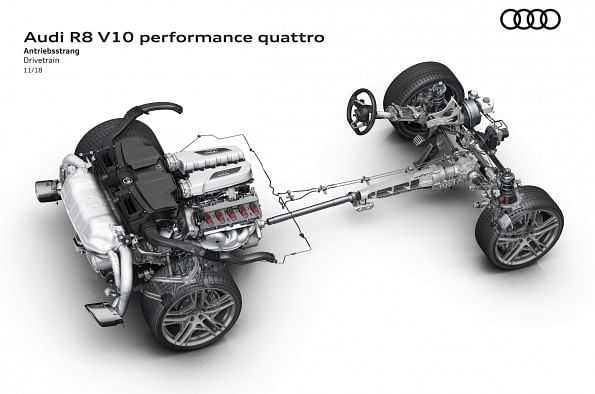

The 2020 Audi R8 V10 is the pinnacle of motorsport engineering from Audi and has been one of the most loved supercars since its launch back in 2006. The latest iteration is powered by a Lamborghini sourced 5.2L naturally-aspirated V10 engine which produces 615 hp in its most powerful avatar. Paired to a dual-clutch 7-speed S-Tronic transmission, the mid-engined supercar accelerates from 0-60 mph in just 3.2 seconds and reaches a mega top speed of 205 mph. All of this superb straight-line and truly incredible cornering performance is thanks to the trick Quattro AWD system.

The AWD system powering the R8 is predominantly rear-biased, just like other Audi S and RS models. But here, the packaging is a bit different. The engine, as we already know, sits in the middle of the chassis for better weight distribution leading to superior performance on track and on the road. The rear differential is housed with the lighting-quick 7-speed dual-clutch transmission and sits behind the engine. The prop shaft connects the drive from the engine to the front axle via a front differential. The differential itself is open but it houses an electromechanical clutch pack that takes the input from multiple sensors and shuffles the drive among the two front wheels within 0.1 milliseconds. And thus, the system is purely automatic without the need of drivers interference.

The characteristics of this system can be altered via a control dial on the steering wheel for various drive modes which alters the amount of power going to the wheels in each mode.

Audi e-tron Quattro AWD system

The 2020 Audi e-tron is the first attempt of Audi to enter a highly developing segment of e-mobility. Its future is bright and soon a lot of leading car manufacturers are going to want a slice of this pie.

The e-tron, as the name suggests, is a fully electric SUV that is powered by two electric motors, one on each axle. The total output stands at 402 hp and 414 lb-ft of max torque in its most potent form. All of this instantaneous power is transferred to the wheels by the motors themselves. There is no traditional gearbox to play with but each of the motors gets their own 1-speed transmission. Just like the traditional Quattro AWD system, here also the system is rear-biased.

Each motor gets its own controlling unit which receives vital information from numerous sensors providing wheel slip, throttle positioning, and motor torque. This system makes it easy to modulate the power between the two axles and now is more accurate than ever. The driver can alter the nature of the system by using the drive select menu by choosing the modes like dynamic, auto, comfort or efficiency. The dynamic mode along with the sports mode for the ESC system makes it possible to drive the e-Tron on the edge, using all of its mega electric power. Here, the rear-biased nature reflects the most as the ESC allows for light drifts if that’s what you fancy.

At the end of the day, the e-tron is an SUV and is expected to tackle the roughest and the nastiest of the terrains with ease. The offroad mode makes use of all that instant electric torque and shuffles it between the axles and can control individual wheels to pull the SUV out without breaking a sweat.